which of the following is a type of machine safeguarding osha 10

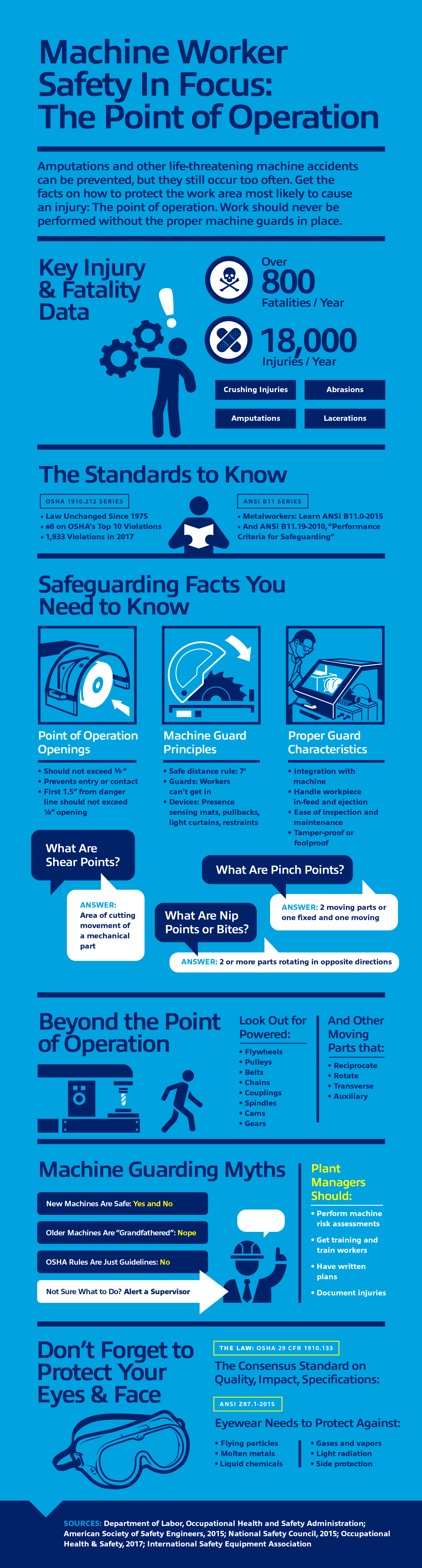

Safeguards are essential for protecting workers from these preventable injuries. To the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding.

Permit safe comfortable and relatively easy operation of the machine.

. A wide variety of mechanical motions and actions may present hazards to the worker. OSHAcademy Course Course 154 Machine Safeguarding. Prevent contact keeping the workers hands arms or any other part safe from the moving part.

A Pullback devices b Safety trip controls c Electro-mechanical sensing device d Two-hand control. All machines consist of three fundamental areas. 29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards including those created by point of operation in-running nip.

A good rule to remember is. These can include the movement of rotating members reciprocating arms and cutting teeth. Meet the minimum OSHA requirements.

A True b False. Criteria for Machine Safeguarding. What are the 2 types of primary safeguarding methods.

OSHA has set out a few general requirements that a safeguard must meet in order to ensure maximum protection. The following are all machine safeguarding requirements except. Controls or attachments that prevent inadvertent access by employees to hazardous machine areas.

Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. There seem to be as many hazards created by moving machine parts as there are types of machines. This problem has been solved.

Feeding and ejection methods is a type of machine safeguarding. The most common types of machine guards are. The following are all machine safeguarding requirements except.

If a new guard causes interference 4. Any machine part function or process that may cause injury must be safeguarded. When you are protected by the with you opera ng the machine safeguards and others in the work 1.

Commonly Used Machine Guards 12 Table 2. Guards provide physical barriers that. Primary Safeguarding Methods Two primary methods are used to safeguard machines.

Be firmly secured and not easily removable. Examples of safeguarding device. It does not specify all machine guarding requirements or all types of machinery or equipment.

Must prevent workers from lubricating a machine without removing the safeguard Which of the following should employers prevent in order to ensure the safety and health of workers in regards to machine guarding. Both types of safeguards need to be properly designed constructed installed used and maintained in good operating condition to ensure employee protection. Machine guarding and related machinery viola-tions continuously rank among the top 10 of OSHA citations issued.

An employee trained on his you can take it off as long as you area are protected also you are. The safeguarding system must have the following features. Replace it at the end of the shi L.

A well-designed safeguarding system makes sure that the moving part is unreachable. When the operation of a machine or. 3 Identifies medical response options and designates an assembly area.

Machine Guarding OSHA 10-Hour Outreach Training General Industry. Herein what are the most common types of machine guarding. _____ True or False.

Various types of machine guards available for machine guarding. Machine Safeguarding Written Program University of California Santa Barbara 1 of 3 This fact sheet provides awareness level information for machine safeguarding and the control of common hazards associated with working with machines as outlined in the Machine Safeguarding Program Go to TOC of program. Prevents employee contact with the hazard area during machine operation.

Rotating in-running nip points reciprocating and transversing are types of hazardous _________. Machine Guarding Introduction. Avoids creating additional hazards.

There are many ways to design and use machine safeguarding. All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks The following are some.

Guards and some types of safeguarding devices. The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the. Which types of moving parts need guarding.

Ensure that no objects can fall into the moving parts. Primary machine can fill in as. Which of the following is a type of machine safeguarding punching.

The point of operation the power transmission device and the operating controls. Any machine part function or process which may cause injury must be machine guarded. Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement.

Due to this fact OSHA Occupational Safety Health Administration has established a set of standards around machine guarding. Criteria for Machine Safeguarding. Prevent workers hands arms and other body parts from making contact with dangerous moving parts.

Machine safeguarding helps protect workers from preventable injuries in all three areas. The following are all machine safeguarding requirements except. Types of Safeguarding Devices 13.

The operator initiates the machine cycle. Good to operate. This OSH Answers fact sheet is based.

Machine guards are essential for protecting workers from needless and preventable injuries. Presence sensing safety trip controls two hand control pull back restraint. 2 Identifies emergencies that might reasonably occur and provides procedures for alerting people about an emergency.

Select the 4 answer options that apply. 1 Assigns responsibilities to those affected and outlines evacuation routes.

Basics Of Machine Guarding Hazards And Solutions March

Basics Of Machine Guarding Hazards And Solutions March

10 Safety Tips For Osha Standards Industrial Safety Industrial Safety Osha Safety Training Health And Safety Poster

Basics Of Machine Guarding Hazards And Solutions March

Professional Portable Fire Extinguisher Training Macon Georgia 770 333 7979 Do Your Emp Fire Extinguisher Training Fire Extinguisher Fire Protection Services

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

Basics Of Machine Guarding Hazards And Solutions March

Basics Of Machine Guarding Hazards And Solutions March

Machine Guarding Safety Instructions Youtube

Machinery Safety Training By Osha

Basics Of Machine Guarding Hazards And Solutions March

Basics Of Machine Guarding Hazards And Solutions March

Crane Balancing Act Truck Cranes Crane Construction

Machine Guard Infographic The Point Of Operation Better Mro

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View